RIB One Prefab is a fully integrated and digitalized production workflow for prefabrication. The intelligent software solution, with a centralized database, enables automated management of the whole prefabrication production process from sales and resource planning to production to logistics and mounting. With an intuitive user interface, the system simplifies workflow management, provides a visual overview of processes, and effortlessly supplies digital instructions to machinery.

It begins with data. It is crucial to effectively manage and process a vast amount of building data before advancing to the production planning stage. That’s why our Smart Planning begins at the initial offer. Manage sales actions, project and procurement planning, and production planning—all in one place.

Automation and digitalization are pivotal to success. Utilizing planned data is crucial for ensuring high-quality and reliable production. While manual work remains indispensable, our goal is to empower your workers, enabling them to maintain productivity while upholding stringent quality standards. Automation allows for a focus on essential manual tasks, while digitalization enhances employee efficiency and accuracy.

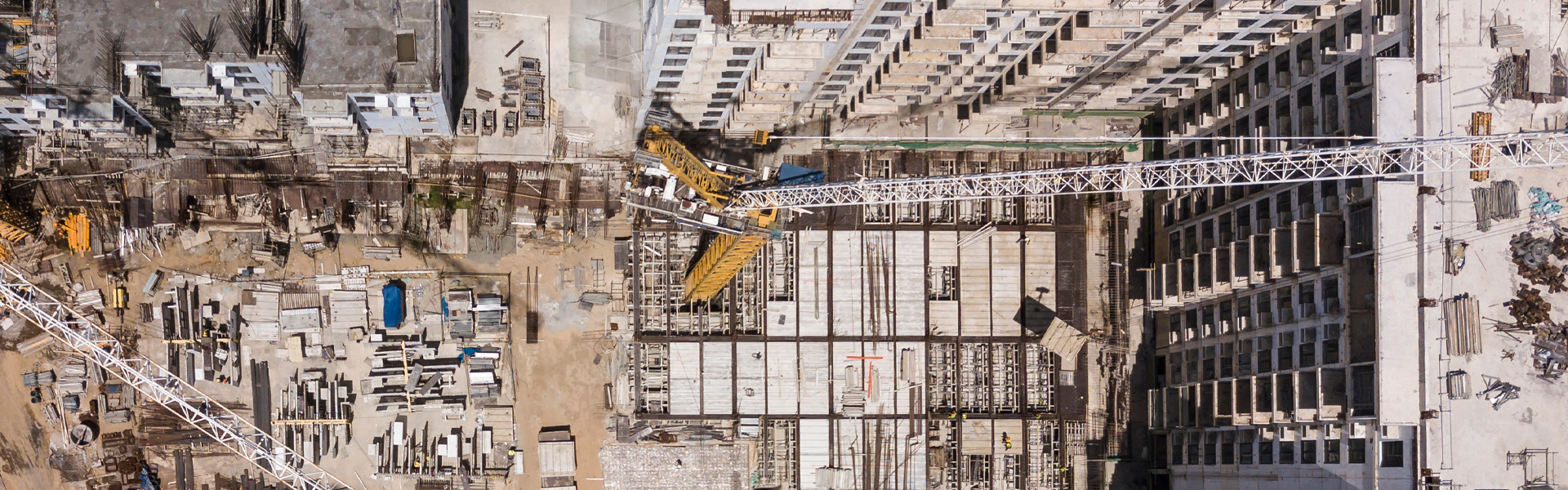

RIB One Prefab extends its advantages beyond the factory gate and onto the construction site. In today’s world, being late with production or delivery is a thing of the past thanks to a holistic logistics approach. You can now stay on top of deadlines and transportation requirements right from the initial planning stages. You’ll have a clear plan for stacking, storage, and delivery for every single element, even before it’s manufactured. That’s logistics excellence in action.

Integrate, Automate, and Optimize Your Precast Operations from Planning to Production

RIB MES is your conduit to meticulously planning and controlling every facet of stationary production. With a backbone of automated planning, pallet nesting and intelligent delivery packages, the leap in production time is significant.

Engage in seamless production of diverse precast elements – be it prestressed flat precast concrete parts, solid walls or slabs on long-line beds. The benefits are palpable: superior quality, optimized processes, and heightened productivity. Now, couple this with RIB Automation, our control systems for all machines necessary in the precast process, from concrete spreaders to vibrating tables and you’re steering a highly efficient stationary precast plant.

Harness the prowess of MES Visuals, projecting precise plans onto the pallet, guiding workers through each step ensuring correct placements. With RIB MES at the helm, revel in streamlined production planning, maximizing your plant’s output through optimal pallet nesting across projects. Embrace Smart Station Technology; touch screens deliver real-time information right at the work stations, significantly cutting down paper usage, and propelling efficiency. Every detail, every process, finely tuned and meticulously orchestrated, ensuring a lean, productive prefab plant ready for the demands of modern construction. Experience the future of precast production with RIB’s innovative solutions.

But we don’t stop there. Extend the automation and digitalization streak with RIB PPS, our adept production planning and scheduling software, orchestrating the whole precast process from procurement to installation. Couple this with our scalable warehouse/stockyard operating solutions, and you’ve got a comprehensive, streamlined operation.

Elevate your stationary precast operations to a pinnacle of efficiency and quality with RIB’s tailored software solutions. Dive deeper into how RIB One Prefab and RIB PPS can redefine your precast production. Contact us today.

DOWNLOAD BROCHURE

At the heart of modern precast production lies the synergy between meticulously planned circulatory systems and innovative automation technology, all under the proficient oversight of RIB MES. With a comprehensive grasp on every nuance of the precast production process, RIB MES orchestrates a smooth, efficient, and cost-effective production journey from inception to completion.

Delve into a realm where precision-engineered workstations and machines, such as shuttering robots, concrete spreaders, and tilting tables, are the stalwarts of production excellence. The circulatory system, a marvel of engineering, seamlessly interacts with these machines, all under the vigilant control of RIB Automation. This robust integration ensures the flawless creation of a myriad of precast products including floor slabs, double walls, and other bespoke concrete elements. The choreography between the circulatory system and the machines, directed by RIB MES, exemplifies a modern, efficient, and scalable production environment.

Extend your control and precision with additional modules of RIB MES. The MES Smart Laser module elevates precision, saving time by aiding workers in achieving pinpoint accuracy. Meanwhile, MES Smart Stations streamline operations by furnishing workers with crucial information on-the-go, significantly reducing management overhead. Not to be overlooked, the MES Quality Management module is your watchdog for quality, meticulously tracking and ensuring the highest standards are met, thereby reducing defects and the subsequent need for reworks.

Transitioning beyond the bustling factory floor, venture into a realm of seamless operations with RIB PPS. This production planning and scheduling marvel ensures a smooth sail from procurement to installation. For the quintessence of organization, our Stockyard/Warehouse solutions are your go-to. Beginning with precise stacking of units, evolve your operations from handheld/QR-based systems to fully automated cranes, ensuring scalability and efficiency every step of the way.

Embrace the future of precast production with us. Reach out today and explore how our holistic solutions, driven by the prowess of RIB MES and Automation, can elevate your precast production operations to a pinnacle of efficiency, quality, and profitability.

DOWNLOAD BROCHURE

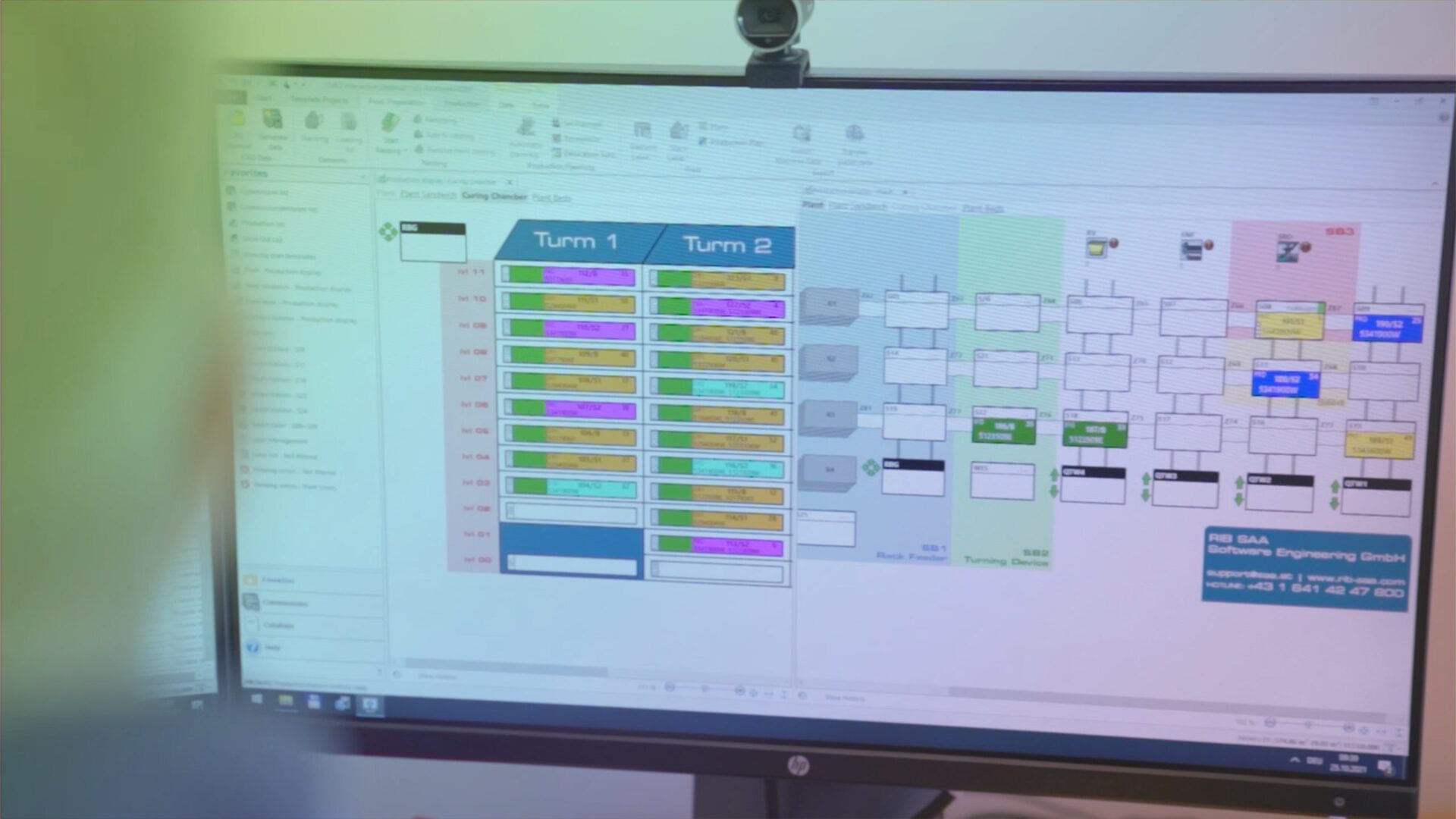

Introducing RIB PPS, an integral component of the RIB 4.0 ecosystem, tailored specifically for precasters, prefab, and modular construction companies. This platform is engineered to take charge of your precast plants, ensuring projects are produced efficiently and delivered on time to the construction site.

RIB PPS synchronizes your data between stakeholders and their software, solving the issue of siloed data and manual conversion of files. By providing a single, central data hub, it streamlines office tasks, planning, and scheduling work, making information easily accessible and actionable. This centralized approach facilitates better communication and coordination among teams, regardless of where your plants are located.

Your precast, prefab or modular plants are the lifeblood of your construction journey, and RIB PPS is engineered to be in absolute command of them. With the flexibility to produce elements in any plant appropriate, it ensures timely arrival at the construction site, irrespective of where your plants are located. The transition from planning to production is simplified, promoting tighter planning and a harmonious production handover. Within the RIB PPS ecosystem, every stakeholder is equipped with a clear roadmap, catalyzing an effortless transition from the drawing board to the field. The result? Your projects evolve from sketches to tangible structures swiftly and accurately.

With RIB PPS, the production handover process is simplified. It is designed to enable tighter planning by providing clear and effective production handover procedures within the RIB One Prefab ecosystem, enabling RIB MES and RIB Automation to reach even further. This translates to smoother transitions from planning to production, ensuring projects stay on track and on budget.

When it comes to stockyard management and transport scheduling, RIB PPS stands out. It helps in planning and monitoring the transportation of your precast products from the plant to the construction site. In this way we ensure that the right products arrive at the right place at the right time, contributing to project timeliness and overall efficiency.

RIB PPS’s integration with the RIB 4.0 ecosystem amplifies its capabilities, offering a harmonized platform for managing various facets of your construction projects. The unified system enhances visibility, control, and coordination across all stages of your construction projects.

Step into a realm of enhanced operational efficiency with RIB PPS. Enhance your production, scheduling, and delivery processes to meet the demands of modern construction projects. Reach out to us today and discover how RIB PPS can be the catalyst for achieving streamlined operations and higher project success rates.

DOWNLOAD BROCHURE

Looking to make your construction process smoother? Our RIB PPS Transport and Installation Scheduling Module is here to help! This software is crafted for construction firms aiming to better manage their transport and installation schedules. It helps you handle installation tasks, organize transport logistics, and easily create detailed reports.

Our module replaces manual steps with automated ones, making it simpler to request resources, allocate them, and sketch out transport plans. This digital shift reduces manual errors, boosts efficiency, and saves precious time. Plus, our module integrates with your current systems, making the switch easy and beneficial right away.

Being a part of the wider RIB 4.0 framework, our module streamlines processes along your entire supply chain. Every phase, from early planning to final billing, is linked and automated. This doesn’t just simplify your workflow, it also gives you a clear picture of your operations, helping you make smarter decisions and enhanced project outcomes.

Ready to advance on your digital journey? Explore the modern way of construction planning with our RIB PPS Transport and Installation Scheduling Module. Get in touch with us to discover how our software can enhance your construction operations.

DOWNLOAD BROCHURE

Our goal is to improve your efficiency and productivity through a range of services, such as implementation, system navigation, and optimizing upgrades. We understand the challenges of meeting deadlines and the need for timely assistance. Our experienced staff, who are seasoned industry-experts, take pride in offering prompt and effective support – just ask our hundreds of thousands of satisfied users!